We aim for economic sustainability by adopting practices that foster long-term economic development while addressing sustainability risks and impacts. This involves balancing the expectations of our shareholders for economic growth and profit with our commitment to minimising environmental and social impacts.

Financial Stability and Revenue Growth

Financial stability and revenue growth are essential for the Group as they ensure continuous operations, maintain market competitiveness and boost stakeholder confidence. These factors help us to remain resilient to economic fluctuations, support sustainable practices, enhance employee welfare and facilitate strategic expansion and diversification.

Our Approach

- Enhance competitiveness in the domestic market by intensify its efforts in providing value-added offerings and services to improve customer satisfaction and loyalty.

- Strengthen our foothold within ASEAN region through the introduction of new touchpoints and vehicle models to drive sales and after-sales service business segments.

- Improve efficiency in financial management through business rationalisation programmes and cost saving initiatives.

Optimum Assets Utilisation And Capital Allocation

Effective use of assets ensures higher returns on investments and reduces waste. Strategic capital allocation helps to prioritise funding for high-impact projects and innovations. These approaches will collectively enhance operational performance, reduce costs and drive sustainable growth, ultimately improving profitability and shareholder value.

Our Approach

- Ensure optimal assembly capacity utilisation at all our assembly and manufacturing plants.

- Strive to maximise the capacity utilisation for our after-sales service centres through improved touchpoints and enhanced customer service.

- Strong discipline in ensuring the delivery of expected return on investments.

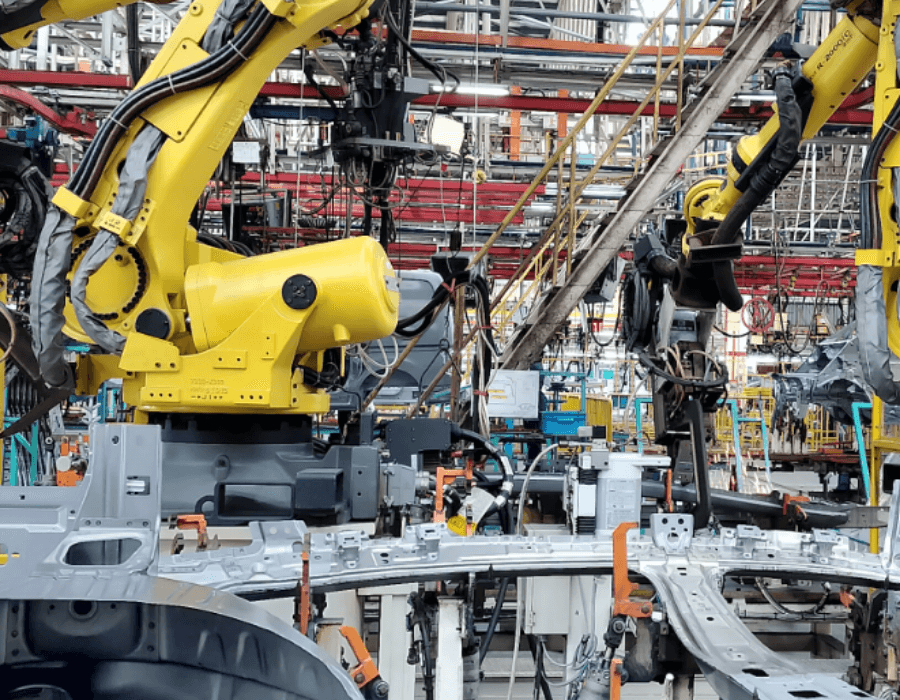

Innovation, Automation And Digitalisation

Technological innovation is key to enhance business operations, improve process efficiency and effectiveness. Automation and digitalisation complement operational processes in enhancing efficiency, reducing operational costs and improving product quality.

Our Approach

- We invest in innovation to drive the development of new and improved products, keeping the Group’s businesses competitive and relevant.

- We invest in robotic and automation especially in our assembly and manufacturing plants to streamline manufacturing processes, increase production speed and minimise errors through precision applications.

- We capitalise on digitalisation to improve data management, customer engagement and decision-making through advanced analytics and connectivity.